Wattle & Daub: Craft, Conservation & Wiltshire Case Study

Contents

Contents

2 History

3 Craft

3.3 Panel Types

3.4 Staves

3.6 Daub

3.7 Decoration

4.1 Soils

4.1.1 Constituents

4.1.2 Plasticity

4.1.3 Strength

4.1.4 Field Testing

4.1.5 Selection

4.2 Dung

4.2.2 Lignin

4.2.3 Urine

4.2.4 Microbial Debris

4.2.5 The Role of Dung

4.3 Fibre

5.2.3 Maintenance

5.3 Repair

5.3.1 Partial Renewal

5.4 Replacement

5.4.1 Brick Infill

5.4.2 Renewal

6.3 Fieldwork

6.5 Evaluation

| Title Page Previous Next | Craft >Withies and Laths |

3.5 Withies and Laths

The malleable twig withies (or ‘wandys’) were

woven around the staves in the same manner as a hurdle or a basket weave, their

direction of entry alternating with each course. The elasticity of the green

withies provided stiffness to the panel. Green cleft oak lath could be woven in

a similar manner, as could thin bark

strips.[28]

Wattle panels were initially of withies, used in the round or split into halves

or slats. Evidence suggests that laths may not have been used until the

14th or

15th century and such early use may

have been a Wessex practice, although withies also continued to be used wherever

the craft prevailed.

For buildings that survive today, the predominant withy material found is hazel. This may not have always been the only wood routinely used. There is evidence that the use of willow (sallow / osiers) was also common, together with a variety of other slender rods of ash, birch, lime and almost any other flexible green woods that were to hand. Reed was also utilised and was particularly suited to close studding.[29]

Laths from the middle ages were usually of oak or beech.[30] During the reign of Edward III, the size was regulated by statute as 1” x ½” and again by statute in 1528 as 5’ x 2” x ½” but are often as wide as 4”. Briggs (1925) states early lathing was nailed on to the frame surface and daubed so the timbers were not on show, but evidence of this practice is not given. Where the laths were nailed to thick staves or studs, the daub was often applied like plaster and the panels were therefore hollow. The void was often filled with straw or bran.

The supply of withies from coppice woods was often in the form of underwood that shared space with timber trees. Managed coppicing was well established by the middle ages, especially in areas of intensive sheep farming such as Hampshire, Wiltshire, West Sussex and Dorset where hurdles were used as fencing [Figur[31]].31 Whilst it is generally accepted that large timbers may have been transported significant distances for the construction of the more substantial house, coppice wood may also have been transported to supply woodless areas, even during the medieval period when the coverage of woodland was not significantly declining. Where managed woods were not available, a local source may have been found from great lengths of[32]edgerow.32 The coppice cycle was typically four to eight years, although underwood may also have been taken when required. Growth of approximately seven years was ideal for producing withies. Since a practical width is approximately 12 to 25mm, large sections could be quartered and small sections or the finer ends could be used whole. The wood was best cut during the winter since there was less sap which weakened it and made it prone to insect and funga[33]attacks.33 However, it needed to be used before it seasoned, otherwise it became too stiff to weave and would snap when bent. On cold days the withies could be softened by warming ov[34] a fire.34 The removal of bark might have been to further reduce the risk of rot and beetle attack, but frequently it was retained.

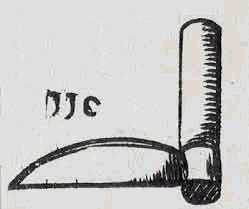

The withies were often worked using a spar hook (or

‘spar knife’), a smaller version of a billhook. It has a thin blade

which is easier to position within narrower withies. The tool has almost

completely vanished, except for a few thatchers and hurdle makers who prefer

them to the larger family member. Where a groove was provided in the sides of

the posts, the ends of the wider withies may have been reduced to fit by cutting

diagonally or removing half of the section using the spar hook or axe [Figure 16].

|

|

|

Lath was riven using a drawknife or a lath-maker’s froe, also known as a lath axe [Figure 17]. Where laths were secured by nailing, a gap was required between adjacent laths to provide a key for the daub. However, when woven, they would be packed tight against each other, as were the withies, since gaps would be created naturally within the weave thickness. Clifton-Taylor (1962) suggests that laths were always nailed yet Rackham has observed the bast fibres (phloem) from lime used [35] string.35 Thompson (2003) suggests that both nails and string may have been used to secure laths to t[36] staves.36 Contradictorily, Wright (1991) says the presence of nails, string or wire indicate later repairs, but evidence of tying both laths and withies suggests otherwise [Figure 18].

[28]

Reid (1989),

p.3.

[29] Clifton-Taylor (1962), p.320, suggests that originally willow (osier), reed, unbarked hazel or ash were all used. He also suggests that laths took over from withies at widely varying dates between the 15th century, possibly earlier, and the 19th century. Bowyer (1973), p.53, says that for square panels (after the demise of close studding around 1550), early work used laths and later work used hazel or ash withies. Wood (1965), p.226 and Salzman (1952), p.188, describe evidence of lathing as early as 1347 at Clare, Essex, Paignton and Winchester and it may have been primarily a Wessex practice at that time. Salzman also offers ‘small braches’, hazel rods, osiers, reeds, thin strips of wood, or other ‘pliant material’. Rackham (1994), p.45, observes that hazel and sallow (willows) are commonest in surviving buildings and has also found elm, aspen, birch, maple and lime. Thompson (2003) has evidence of laths of oak, Scots Pine, and withies of hazel and many other materials including birch, ash, etc. Wright (1991), p.97, has evidence of reed used for close studding.

[29] Clifton-Taylor (1962), p.320, suggests that originally willow (osier), reed, unbarked hazel or ash were all used. He also suggests that laths took over from withies at widely varying dates between the 15th century, possibly earlier, and the 19th century. Bowyer (1973), p.53, says that for square panels (after the demise of close studding around 1550), early work used laths and later work used hazel or ash withies. Wood (1965), p.226 and Salzman (1952), p.188, describe evidence of lathing as early as 1347 at Clare, Essex, Paignton and Winchester and it may have been primarily a Wessex practice at that time. Salzman also offers ‘small braches’, hazel rods, osiers, reeds, thin strips of wood, or other ‘pliant material’. Rackham (1994), p.45, observes that hazel and sallow (willows) are commonest in surviving buildings and has also found elm, aspen, birch, maple and lime. Thompson (2003) has evidence of laths of oak, Scots Pine, and withies of hazel and many other materials including birch, ash, etc. Wright (1991), p.97, has evidence of reed used for close studding.

[30]Briggs

(1925), p.233.