Wattle & Daub: Craft, Conservation & Wiltshire Case Study

Contents

Contents

2 History

3 Craft

3.3 Panel Types

3.4 Staves

3.6 Daub

3.7 Decoration

4.1 Soils

4.1.1 Constituents

4.1.2 Plasticity

4.1.3 Strength

4.1.4 Field Testing

4.1.5 Selection

4.2 Dung

4.2.2 Lignin

4.2.3 Urine

4.2.4 Microbial Debris

4.2.5 The Role of Dung

4.3 Fibre

5.2.3 Maintenance

5.3 Repair

5.3.1 Partial Renewal

5.4 Replacement

5.4.1 Brick Infill

5.4.2 Renewal

6.3 Fieldwork

6.5 Evaluation

| Title Page Previous Next | History |

2 History

The origins of wattle and daub stem from the primitive

buildings, where huts were constructed of poles and earthen walls. Archaeology

shows the techniques were numerous and their boundaries ill-defined. Earth

walling could be used simply as a base for a roof, or higher walls could be

formed to raise the roof away from the ground. The walls could be made with

wattles, woven from brushwood or ‘withies’ (thin wands) coppiced

from nearby woodlands. These wattle walls, bearing no significant difference to

the construction of hurdles, used the same technique as fencing for boundaries,

penning, wind-resistance and privacy and those laid flat as tracks [Figure 1].

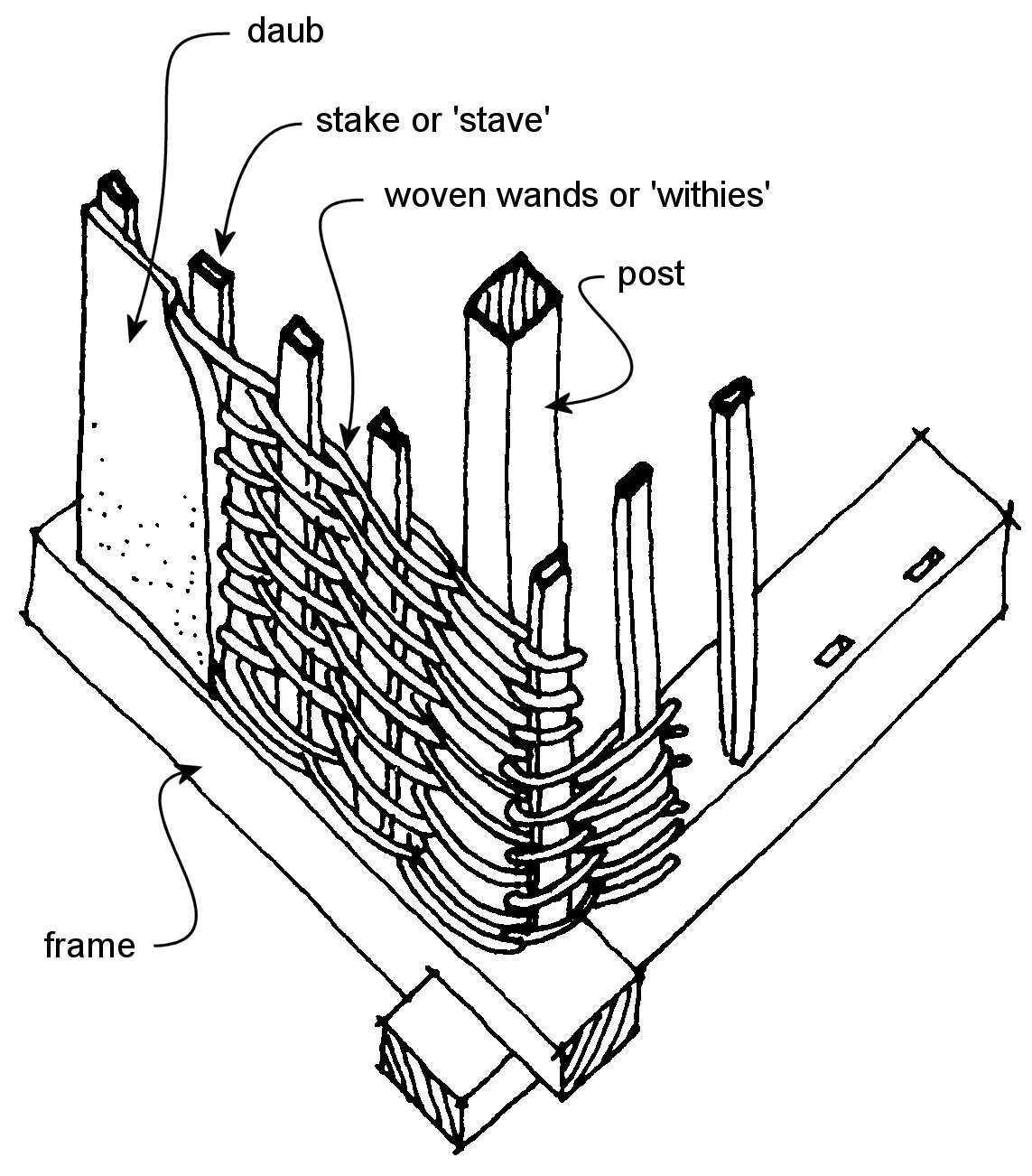

Figure

2. The principal method of wattle and daub walling,

established by the Iron Age. From Bowyer (1973).

The filling of these wattle walls to improve wind resistance

could be achieved with anything that came to hand, but most frequently may have

been straw, moss, leaves and earth. For easy layering, the use of turf and

topsoil was common, but for binding into wattles, it was easier to use soil that

could be pressed into position and would remain in place. This common form of

wattle and daub walling was being practiced at least as early as the Iron Age.

Archaeology from Meare near Glastonbury in Somerset shows structural vertical

poles were driven into the earth and the wall completed with wattles and

clay.[1]

Occasionally the daub was burnt, either accidentally or deliberately, which

hardened the surface like fired pottery. In areas rich in timber, a more

sophisticated construction was used whereby a stone or timber cill provided a

firm base for split timbers and holes for the staves provided a positive

location for the wattles that may have kept them from bowing or coming detached

in high winds [Figure 2].

The arrival of the Romans into Britain did little to affect the use of wattle and daub since it was developed into their own Romano-British styles of construction. As indigenous materials they were highly suitable, yet, as Vitruvius describes, it was not the preferred method in their native Rome, [2]

‘As for "wattle and daub" I could wish that it had

never been invented. The more it saves in time and gains in space, the greater

and the more general is the disaster that it may cause; for it is made to catch

fire, like torches. It seems better, therefore, to spend on walls of burnt

brick, and be at expense, than to save with "wattle and daub," and be in danger.

And, in the stucco [plaster] covering, too, it makes cracks from the inside by

the arrangement of its studs and girts [rails]. For these swell with moisture as

they are daubed, and then contract as they dry, and, by their shrinking, cause

the solid stucco to split. But since some are obliged to use it either to save

time or money, or for partitions on an unsupported span, the proper method of

construction is as follows. Give it a high foundation so that it may nowhere

come in contact with the broken stone-work composing the floor; for if it is

sunk in this, it rots in course of time, then settles and sags forward, and so

breaks through the surface of the stucco covering.’

The bases of Anglo-Roman walls may often have been embedded

in concrete and the surfaces plastered. Remains of daub from Verulamium,

Hertfordshire, show herringbone keying of the daub surface that indicates it had

a plaster

finish.[3]

Chopped straw, hay, vegetable materials and dung were added to the daub to

improve binding and reduce shrinkage cracking.

The method prevailed through the Saxon period. A quantity of a Saxon plaster has been recovered from various sites in Wiltshire that has impressions of wattles and timber beams.[4] Excavations at Thetford found wattle and daub used in the 9th century building although evidence from excavations of 7th and 10th century buildings shows that the Saxons may have preferred planking.[5]

Wattle and daub was also widespread throughout many other countries, such as used by the Normans prior to their 11th century invasion of England. Although the surviving Anglo-Norman buildings are of stone, the majority were timber framed and so continued to utilise wattle and daub. These structures have all but gone although much archaeological evidence has been found, including a daub probably consisting wholly of animal dung.[6]

As the craft of the English carpenter evolved, so did the form of timber-frame construction. In areas with cruck construction, vertical walls were created by creating panels dropping below the level of the cruck ‘spurs’ and these were then finished with wattle and daub. In these and other areas of the country, the initial abundance of wood allowed the structural framing to include a large number of supporting posts.[7] These ‘close-timbered’ or ‘close-studded’ walls required a different form of infill to their narrow panels. Instead of wattling, straight laths were held in place by channels formed in the sides of the posts and these were then daubed. The infill was always (and unfortunately still is) considered secondary to the timber posts and studs. It was only the scarcity of timber from the 16th century onwards that increased the ratio of infill to timber walling.[8] Ironically, the wider panels required intermediate support between studs, and therefore the use of staves and woven wattlework returned once more to substantial houses.

Also during the

16th century, it became common for

new houses to have a fireplace rather than central hearth. This was formed by a

smoke bay in which two trusses were extended downwards or by provision of a

timber framed smoke hood, both filled with wattle and

daub.[9]

Most histories of construction in England focus on the developing crafts of the yeoman’s house and the great buildings of the wealthy: only cursory mentions of the cottage homes of the peasantry are provided. This is mainly due to the limited archaeological remains but it is clear that wattle and daub invariably completed the walls of the true cottages that existed throughout the country down to the 19th century.

In all buildings, a disadvantage of wattle and daub has always been its vulnerability to damp. If not kept dry, the wattles would rot or be attacked by beetles and the daub would crack and lose key due to wetting and frost. This would be worse along the bottom of the external walls and it has been suggested that the jettied frame evolved as a way to keep the walls drier. The effects of rain were retarded by the usual limewash finish but could be further reduced by finishing the panel with a lime plaster. This provided a more robust surface and sealed the cracks in the underlying daub. However, the inherent flexibility of the frame and the shrinkage of earth and lime materials meant that not even the finest work could seal the joint between panel and its surrounding frame. Compared to masonry walls, wattle and daub buildings were draughty and the panels required frequent repair or renewal. In the east of England improved weather resistance of both frame and panels came from plastering the entire wall, often accompanied by decorative plaster known as pargetting.

Salzman (1952) gives a comprehensive account of references to wattle and daub through the ages: it is also referred to as ‘ruddle and dab’ and ‘wattle and dab’.[10] The withy or wreathing rods are mentioned in 1223 at Winchester as ‘ad walduram’, in Monmouth in 1370 as ‘wyndend’ and at Bath in 1435 as ‘watyll’. In 1441 there is ‘pro vrethying et dawbying’ and in 1535 ‘frithying roddes’.

At York, in 1327, is recorded the mixing of earth with straw

and stubble for use by a ‘torcher’ or ‘dauber’. The term

torching was often applied to the process of covering and was applied to walls

as well as the insides of roofs and chimney linings (parging). The daubing was

often referred to as ‘rudyng’ or simply as earthing or

‘terrying’ (from latin ‘terrand’) but most frequently as

daubing (‘dauband’ or

‘daealband’).[11]

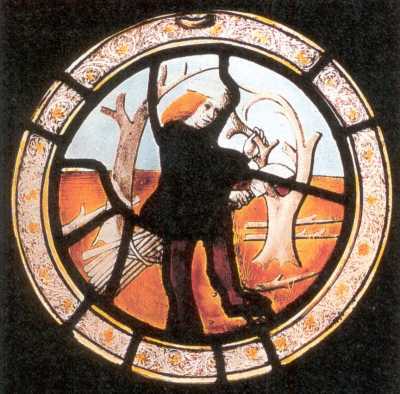

Figure

3. ‘Lopping and topping’ from coppice woods.

15th Century. From Nicholson and

Fawcett (1988).

In primitive and peasant building the wattle and daub work

would have been done by the house

owner.[12]

The peasant would construct his home from slender timbers and use the early

customary right to ‘lopping and topping’ to provide wood, often oak

or ash, for wattling [Figure 3]. From the

11th century, managed coppicing

would secure a supplier of these underwoods. This may have been daubed

with earth, straw and dung. Chalk or lime may have been added where available.

For wealthier owners, the work may have been done by a dauber (torcher),

the workmen often referred to as ‘daubatores’ or

‘dealbatores[13].13

The position of the dauber within the crafts was well established, as

illustrated as early as 1212 in a list of maximum

dail[14]wages,14

‘Carpenters – 3d. and their food or 4d.

without food; Masons and tilers, the same; Freemasons, 2½d. or 4d.;

Plasterers, daubers, and puggers 2d. or 3d.; their assistants, 1½d. or

2d.’

and by the 1351 Statute of

Labourers,[15]

‘tilers 3d., and their mates 1½d.; plasterers

and other workers of mud walls, and their mates, likewise.’

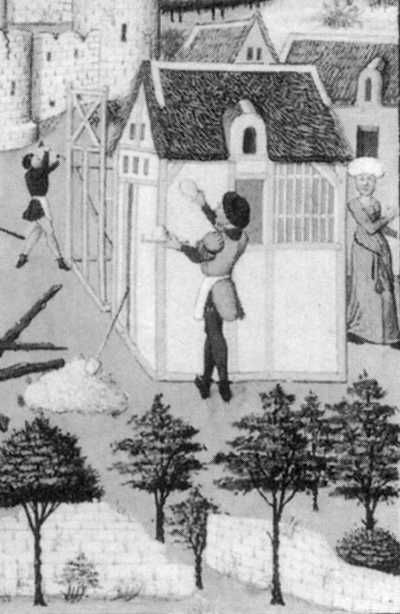

This also shows that whilst considered skilled craftsmen,

the plasterers and daubers were less well regarded than the carpenters and

masons who may have designed the house as well as constructed it [Figure 4].

These skills were always in short supply and this meant that daubers would often travel. In 1487 at Urchfont, Wiltshire, there is reference to a dauber that came from outside the village,[16]

These skills were always in short supply and this meant that daubers would often travel. In 1487 at Urchfont, Wiltshire, there is reference to a dauber that came from outside the village,[16]

‘William Dicial – for daubing walls for 30

days at 4d. per day.’

Figure

4. A 15th

century artisan plasterer completing infill panels after the carpenter had

finished his work. From Binding (2001).

The craft of wattling was also close to that of the thatcher

and generally grouped as ‘helyers’ (helliers) or

‘cooperatores’. It is therefore likely that the crafts could be

combined, as suggested by the payment of 17d. in 1500 at Grendon for new spars

and wattling, although the latter could have been used under thatch rather than

for

walls.[17]

The thatcher required coppice wood for spars and liggers, as did the plasterer

for staves and withies. Both also most commonly used straw.

The demise of the craft of daubing was driven by several compounding factors. Firstly was the replacement with brick nogging.[18] Secondly, timber framing, using either new or reused timbers, diminished during the 17th and 18th centuries due to the inherent fire risk and the subsequent move to stone and brick: construction of half-timbered buildings had almost ceased by the turn of the 18th century. Thirdly, as half-timbering became less respectable through the 18th century Palladians’ desire for stone or brick façades, timber walls were frequently modernised by full plastering or by hiding behind mathematical tiles.

The poor image of wattle and daub was even conveyed through

law: it is said that the term ‘breaking and entering’ comes from the

ease with which criminals were able to enter a building by breaking through the

infill.[19]

More recently, as new materials became abundant during the

20th century, many creative ways of

replacing or ‘improving’ wattle and daub have been tried. Where the

timbering remains exposed, panels have often been repaired with a cement render.

Further, where not controlled by listed buildings legislation, instead of

replacing with brick there has been a trend for using fibre board, expanded

metal lath and similar backing materials.

It is remarkable that this method of walling remained one of the most common and unchanging forms of walling from primitive building down to its gradual demise during recent centuries. Throughout these periods of great changes and innovation, the craft remained almost entirely unaltered despite the huge developments in the carpentry of timber framing that surrounded each panel. Not only did the methods used for wattle and daubing remain consistent, but also did the majority of the materials used.

It is remarkable that this method of walling remained one of the most common and unchanging forms of walling from primitive building down to its gradual demise during recent centuries. Throughout these periods of great changes and innovation, the craft remained almost entirely unaltered despite the huge developments in the carpentry of timber framing that surrounded each panel. Not only did the methods used for wattle and daubing remain consistent, but also did the majority of the materials used.

[1]

Bowyer (1973), pp.48-51.

[2]

Vitruvius (1960), pp.57-58.

[3]

Davey (1961), p.40-41.

[4]

In the 1970’s, Roy Canham of Wiltshire County Council excavated Saxon

plasters which are now preserved in the Swindon Museum

stores.

[5] Wood (1965), p.212.

[5] Wood (1965), p.212.

[6]

Macphail, Cruise, Allen, Linderholm, Reynolds

(2004).

[7]

Greensted Church, probably dating from before the Norman conquest has adjacent

timber posts which avoided the need for any intermediate ‘beame

fillyng’. However, according to Salzman (1952) p.192, it is likely such a

construction would be beyond the reach of most owners and that some infill, to a

lesser or greater extent, would be required in all

buildings.

[8] Bowyer (1973), p.53.

[8] Bowyer (1973), p.53.

[9]

Slocombe (1988), p.36.

[10]

Reid (1989) states that ‘ruddle and dab’ was a reference to the

‘stud and mud’ of the northwest of England rather than wattle and

daub: the former more accurately being a merger of wattle and daub and

structural cob construction. Bankhart (1908) refers to the term

‘dab’ which was in use in Kent at the turn of the twentieth

century.

[11]

Salzman (1952), pp.188-189.

[12]

Nicholson and Fawcett (1988),

p.34.

[13] Salzman (1952), p.190, states that the term dealbatores more commonly referred to whitewashers.

[14] Ibid., p.68.

[13] Salzman (1952), p.190, states that the term dealbatores more commonly referred to whitewashers.

[14] Ibid., p.68.

[15]

Ibid., p.72.

[16]

Urchfont Parish Millennium Group (2001), p.113.

[17]

Bowyer (1973), p.171.

[18]

As brick production became increasingly economic during the

16th century, it became a common

replacement for decayed wattle and daub panels and, in some districts, it was

also used as infill for new timber buildings. The bricks would be laid either at

an angle, in a herringbone pattern, but more commonly would be laid horizontally

(Reid, 1989). The skill required to replace with brick was considerably less

than wattle and daub, as has remained the case to the present day. However, a

single brick thickness is draughtier than wattle and daub as it sits relatively

loosely between the timber frame and is probably less resistant to the passage

of moisture.

[19]

Hanawalt (1986), p.34