Wattle & Daub: Craft, Conservation & Wiltshire Case Study

Contents

Contents

2 History

3 Craft

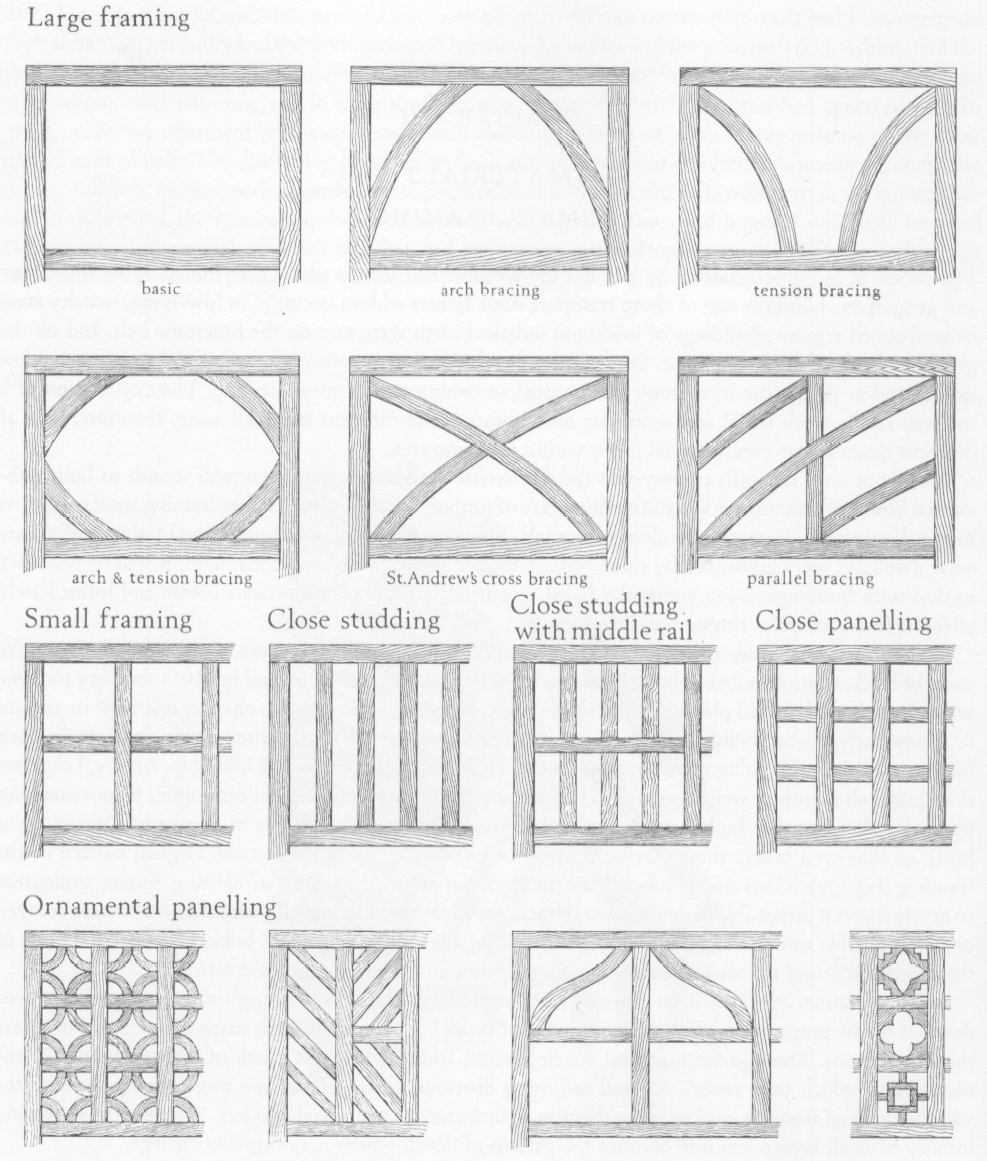

3.3 Panel Types

3.4 Staves

3.6 Daub

3.7 Decoration

4.1 Soils

4.1.1 Constituents

4.1.2 Plasticity

4.1.3 Strength

4.1.4 Field Testing

4.1.5 Selection

4.2 Dung

4.2.2 Lignin

4.2.3 Urine

4.2.4 Microbial Debris

4.2.5 The Role of Dung

4.3 Fibre

5.2.3 Maintenance

5.3 Repair

5.3.1 Partial Renewal

5.4 Replacement

5.4.1 Brick Infill

5.4.2 Renewal

6.3 Fieldwork

6.5 Evaluation

| Title Page Previous Next | Craft >Frame Preparation |

3.2 Frame Preparation

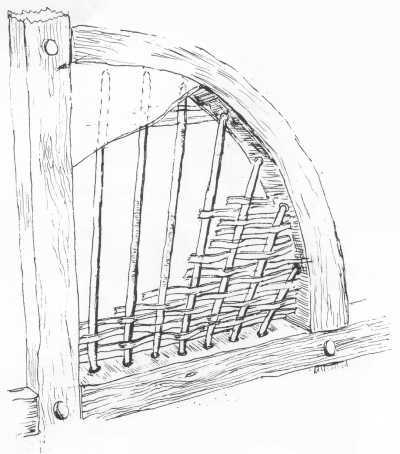

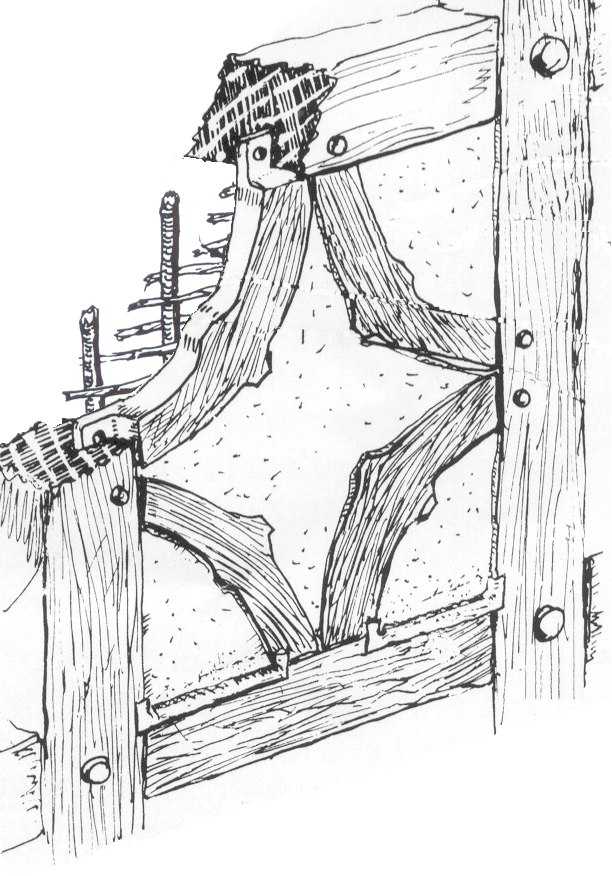

Before the dauber could carry out his craft, it was

necessary for the carpenter to provide the correct detailing to his frame in

order to accept the staves of the wattle panel. The bottom timber would be

either part of a cill beam, mid rail (bressumer) or nogging and, before

construction, the carpenter would gouge a long continuous groove along the

centre-line of its upper face. The top of the panel may similarly have been

formed by a mid rail or wall plate, onto which the carpenter would use an auger

to prepare holes spaced approximately 250-450mm apart, ensuring that one was

placed 0-50mm in from each end. Less commonly, the stave holes were made into

rectangular mortices, rough v-groove mortices or a continuous v-slot gouged on

the soffit (underside) to match the lower rail [Figu[22]].22

Sometimes, the end staves were run into the same mortice as the adjacent

structur[23]

timber.23

The carpenter frequently provided additional grooves along the inside faces of

the posts or studs to accept laths or, occasionally, the ends of withies [Figure 9].

|

|

||

|

|||

|

|

|

||